Introduction

Silk is renowned globally as one of the most luxurious and versatile fabrics, prized for its softness, strength, and shimmering appearance. This introductory section sets the stage by exploring the origins of silk, its historical significance, and an overview of its unique properties that have made it a coveted textile for millennia.

1. What is Silk?

Silk, a natural protein fiber produced by silkworms, has captivated civilizations for centuries with its lustrous sheen and fine texture. This section delves into the basics of silk, tracing its origins and early production techniques that originated in ancient China.

Definition and Origin of Silk

Silk is a natural fiber spun by silkworms during their larvae phase, primarily to form cocoons. The fiber consists of fibroin, a protein that is extruded from the silkworms’ glands and solidifies into silk threads upon exposure to air. Historically, silk production was a closely guarded secret in China, with its discovery attributed to the Empress Leizu around 2700 BCE, according to legend.

Historical Significance

Silk holds immense cultural and economic significance in ancient civilizations such as China, Persia, and Rome. It was highly valued for its luxurious feel and was often reserved for royalty and nobility. The Silk Road, an ancient trade route stretching from China to Europe, facilitated the spread of silk and contributed to its prestige and demand across the globe.

2. Chemical Composition and Structure of Silk

Silk’s molecular structure, primarily composed of fibroin proteins, contributes to its exceptional properties. This section delves into the scientific aspects of silk, examining its chemical composition and structural characteristics that set it apart from other textile fibers.

Molecular Structure of Silk

Silk consists primarily of fibroin proteins, organized in a crystalline structure interspersed with amorphous regions. The unique arrangement of amino acids in fibroin, notably glycine, alanine, and serine, contributes to silk’s strength and resilience.

Comparison with Other Textile Fibers

Silk’s chemical properties, such as its protein-based composition and molecular structure, distinguish it from synthetic fibers like polyester and natural fibers such as cotton and wool. This section highlights how silk’s molecular makeup influences its physical attributes and performance in various applications.

3. Why is Silk So Strong?

Silk is renowned for its remarkable strength relative to its weight, a property attributed to its molecular and structural characteristics. This section explores the factors that contribute to silk’s strength and durability, providing insights into its microscopic composition and intermolecular forces.

Structural Analysis of Silk Fibers

At the microscopic level, silk fibers exhibit a hierarchical structure characterized by crystalline regions embedded in an amorphous matrix. This arrangement enhances silk’s tensile strength and resistance to deformation.

Crystalline Structure and Strength

The crystalline regions of silk fibers, comprising regularly arranged beta sheets, contribute significantly to its strength. These beta sheets are stabilized by hydrogen bonds between adjacent protein chains, imparting rigidity and structural integrity to the fiber.

Role of Hydrogen Bonds and Intermolecular Forces

Hydrogen bonds between amino acid residues in silk proteins play a crucial role in maintaining the fiber’s cohesion and strength. These bonds allow silk fibers to withstand considerable stress and deformation without breaking, making it an ideal material for applications requiring durability and longevity.

4. The Softness of Silk Explained

In addition to its strength, silk is celebrated for its unparalleled softness and smooth texture, making it a preferred choice for high-end apparel and luxurious bedding. This section explores the factors underlying silk’s soft tactile feel and its interaction with the skin.

Factors Contributing to Silk’s Soft Texture

Silk’s softness is attributed to its fine fiber diameter, which creates a smooth surface that glides over the skin. The inherent elasticity of silk fibers further enhances its comfort and drape, conforming gently to body contours.

Surface Properties and Skin Interaction

Silk’s surface properties, including its low coefficient of friction and ability to absorb moisture, contribute to its comfort and suitability for sensitive skin. Unlike synthetic fibers, silk allows the skin to breathe, regulating temperature and maintaining optimal moisture levels.

Comparison with Other Fibers

Compared to cotton and synthetic fibers, silk offers superior softness and luxurious feel due to its natural protein structure and smooth surface. This section contrasts silk’s tactile properties with those of other textiles commonly used in apparel and home furnishings.

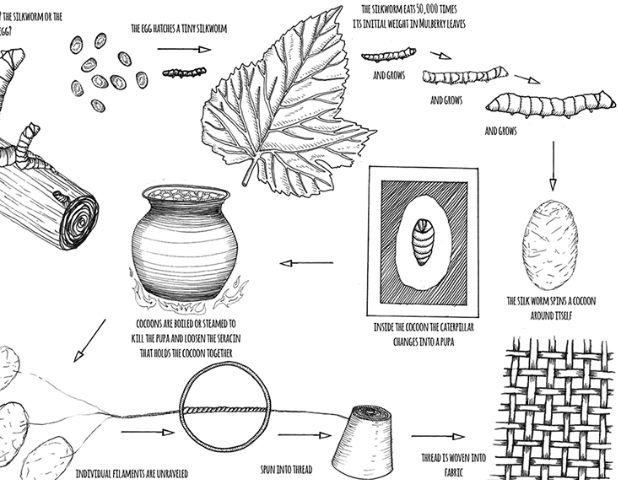

5. Silk Production Process

The journey from silkworm to finished fabric involves meticulous stages of cultivation, harvesting, and processing. This section provides a comprehensive overview of the silk production process, highlighting key steps that transform raw silk into the exquisite textile cherished worldwide.

Sericulture: Cultivation of Silkworms

Silk production begins with sericulture, the cultivation of silkworms on mulberry plantations. Silkworms, primarily Bombyx mori, are reared under controlled conditions to ensure optimal growth and silk production.

Reeling: Harvesting Silk Filaments

During the cocooning stage, silkworms spin continuous silk filaments around themselves to form protective cocoons. The reeling process involves carefully unwinding these filaments from the cocoons, ensuring minimal breakage and maintaining the integrity of the silk fibers.

Weaving: Fabrication of Silk Fabric

Once harvested, silk filaments undergo weaving to create various types of silk fabric safety , ranging from delicate chiffon to luxurious satin. Traditional weaving techniques preserve silk’s natural luster and drape, enhancing its aesthetic appeal and functional properties.

6. Properties of Different Types of Silk

Silk encompasses a diverse range of types, each distinguished by unique characteristics suited to specific applications and preferences. This section explores the properties of popular silk varieties, including mulberry, tussar, muga, and eri silk, highlighting their strengths, softness, and textural differences.

Mulberry Silk

Renowned for its fine texture and uniform color, mulberry silk is the most common variety produced globally. Its smooth surface and superior dye affinity make it ideal for high-end apparel, scarves, and bedding.

Tussar Silk

Distinctive for its natural gold hue and textured appearance, tussar silk is cultivated primarily in India and Southeast Asia. Its coarse fibers lend themselves to traditional garments, sarees, and upholstery, adding a rustic charm to textile applications.

Muga Silk

Native to Assam, India, muga silk is prized for its golden sheen and exceptional durability. The natural luster of muga silk enhances its luxurious appeal, making it a preferred choice for ceremonial attire and luxury garments.

Eri Silk (Peace Silk)

Known for its softness and warmth, eri silk is produced from the domesticated silkworm Samia ricini. Unlike other silk varieties, eri silk is harvested without harming the silkworm, aligning with ethical and sustainable practices in textile production.

Comparative Analysis

This section contrasts the properties of different silk types, including their tensile strength, dye uptake, and suitability for various applications. Understanding the distinct characteristics of each silk variety enables informed decisions in selecting the appropriate fabric for specific projects.

7. Applications of Silk in Various Industries

Silk’s exceptional properties extend its utility beyond fashion and apparel, encompassing diverse applications in home furnishings, medical textiles, and industrial sectors. This section explores the multifaceted uses of silk and its contribution to innovation and functionality across industries.

Fashion and Apparel

Silk remains synonymous with luxury in fashion, renowned for its elegant drape and vibrant sheen. From haute couture gowns to everyday essentials like blouses and ties, silk’s versatility in apparel design underscores its enduring appeal among designers and consumers alike.

Home Furnishings

Silk’s lustrous appearance and tactile softness make it a preferred choice for home furnishings, including upholstery, drapery, and bedding. Silk fabrics enhance interior spaces with their natural sheen and luxurious texture, offering comfort and aesthetic refinement.

Medical and Industrial Applications

Silk’s biocompatibility and mechanical properties make it suitable for medical textiles, such as sutures, implants, and wound dressings. In industrial settings, silk is utilized in technical textiles for its strength, resilience, and thermal stability, supporting applications in aerospace, filtration, and protective gear.

8. The Future of Silk: Innovations and Sustainability

Advancements in silk production and manufacturing are driving innovations that expand its applications and enhance sustainability. This section explores emerging trends and technologies shaping the future of silk, alongside efforts to promote eco-friendly practices in silk farming and textile production.

Emerging Trends in Silk Production

Technological innovations, such as genetic engineering and biotechnology, are revolutionizing silk production by enhancing yield, quality, and sustainability. Advances in spinning techniques and fabric finishing are optimizing silk’s performance attributes for diverse applications.

Sustainable Practices in Silk Farming

Growing demand for sustainable textiles has prompted initiatives to promote ethical silk farming practices, including organic cultivation methods and humane treatment of silkworms. Eco-certifications and traceability systems ensure transparency in the silk supply chain, supporting consumer preferences for environmentally responsible products.

Silk farming, traditionally known as sericulture, has a rich history dating back thousands of years. Today, amidst growing concerns over environmental impact and ethical considerations, the silk industry is increasingly adopting sustainable practices to meet consumer demand for eco-friendly textiles. This article explores the evolution of silk farming towards sustainability, examining the methods, challenges, and innovations driving this transformation.

1. Introduction to Silk Farming

Silk farming involves the cultivation of silkworms for the production of silk fibers, primarily sourced from the larvae of the Bombyx mori moth. The process begins with sericulture, where silkworms are reared under controlled conditions to optimize their growth and silk production. The traditional methods of silk farming have evolved over centuries, influenced by cultural practices and technological advancements.

Historical Context

Silk production originated in ancient China and spread along trade routes such as the Silk Road, influencing global commerce and cultural exchange. Historically, sericulture was a closely guarded secret in China, contributing to its economic significance and prestige.

Modern Silk Farming Practices

Contemporary silk farming integrates traditional techniques with modern innovations to enhance efficiency, quality, and sustainability. The cultivation of silkworms involves stages such as egg production, larvae rearing, cocoon harvesting, and silk processing, each requiring careful management to ensure optimal fiber yield and quality.

2. Environmental Impact of Silk Farming

The environmental footprint of silk farming includes land use, water consumption, energy use, and chemical inputs. Sustainable practices aim to minimize these impacts while preserving natural resources and biodiversity.

Land Use and Deforestation

Silk production relies on mulberry trees as the primary food source for silkworms. Sustainable farms promote agroforestry practices, integrating mulberry cultivation with other crops to optimize land use and prevent deforestation.

Water Consumption and Efficiency

Water is essential for mulberry cultivation and silk processing. Sustainable farms implement water-saving technologies such as drip irrigation and rainwater harvesting to reduce consumption and minimize environmental impact.

Energy Use and Renewable Energy

Energy-intensive processes in silk production, such as cocoon drying and reeling, are being optimized through energy-efficient equipment and renewable energy sources like solar power.

Chemical Inputs and Pollution

Pesticides, fertilizers, and chemicals used in mulberry cultivation and silk processing can pose risks to soil, water quality, and biodiversity. Sustainable farms prioritize organic farming practices, integrated pest management (IPM), and natural dyeing processes to minimize chemical inputs and pollution.

3. Organic Silk Farming Practices

Organic silk farming adheres to strict standards for environmental sustainability and animal welfare, ensuring the production of chemical-free, eco-friendly silk fibers. Certified organic silk meets criteria established by international organizations and regulatory bodies.

Principles of Organic Silk Farming

Organic silk farming prohibits the use of synthetic chemicals, genetically modified organisms (GMOs), and harmful pesticides. It promotes biodiversity conservation, soil health, and natural resource management through sustainable agricultural practices.

Certification and Standards

Certification bodies such as Global Organic Textile Standard (GOTS) and Organic Content Standard (OCS) verify compliance with organic farming principles from farm to finished product. Organic silk certification provides transparency and assurance to consumers seeking sustainable textiles.

Benefits of Organic Silk

Organic silk offers numerous benefits, including reduced environmental impact, improved soil fertility, and enhanced biodiversity. It supports ethical consumer choices and promotes sustainable livelihoods for silk farmers and rural communities.

4. Humane Treatment of Silkworms

Ethical considerations in silk farming extend to the welfare of silkworms during the rearing and harvesting process. Ethical practices aim to minimize stress and maximize comfort for silkworms, aligning with principles of animal welfare and compassionate farming.

Silkworm Life Cycle and Welfare

Silkworms undergo a metamorphic life cycle, from egg to larva to pupa, during which they spin cocoons composed of silk fibers. Ethical silk farming prioritizes humane treatment throughout each stage, ensuring adequate nutrition, space, and environmental conditions for silkworms.

Ahimsa Silk (Peace Silk)

Ahimsa silk, also known as peace silk, offers an ethical alternative by allowing silkworms to complete their life cycle and emerge as moths before harvesting the silk cocoons. This method avoids harm to silkworms and promotes cruelty-free silk production.

Certification and Labeling

Certified ethical silk products, such as those bearing the Ahimsa silk label, provide assurance of humane treatment and respect for silkworm welfare. Consumers can choose products aligned with their ethical values and support sustainable silk farming practices.

5. Innovations in Silk Production

Technological advancements are driving innovations in silk production, enhancing efficiency, quality, and sustainability across the industry. These innovations encompass breeding techniques, silk spinning technologies, and alternative protein sources for silk production.

Genetic Improvement of Silkworms

Selective breeding and genetic engineering techniques aim to enhance the productivity and resilience of silkworms, optimizing silk yield and fiber quality while reducing environmental impact.

Sustainable Silk Spinning

Advancements in silk spinning technologies, such as automated reeling machines and eco-friendly spinning processes, improve fiber strength and uniformity while minimizing waste and energy consumption.

Alternative Silk Proteins

Research into alternative protein sources for silk production, including bioengineered silk proteins and silk-like materials derived from renewable resources, explores sustainable alternatives to traditional silkworm-derived silk.

6. Traceability and Supply Chain Transparency

Traceability in the silk supply chain ensures accountability and transparency from farm to finished product, enabling consumers to make informed choices about their purchases and support sustainable practices.

Supply Chain Management

Traceability systems track the journey of silk fibers from silk farms and spinning mills to textile manufacturers and retailers. Certification programs and digital platforms enhance supply chain transparency, providing detailed information on production methods, environmental practices, and ethical standards.

Consumer Awareness and Education

Educational initiatives and awareness campaigns educate consumers about the importance of traceability and sustainable sourcing in silk production. Transparent labeling and product information empower consumers to support ethical brands and drive demand for responsibly sourced silk products.

7. Challenges and Opportunities

Despite progress in sustainable silk farming, the industry faces challenges such as resource constraints, market dynamics, and socio-economic factors. Addressing these challenges presents opportunities for innovation, collaboration, and positive impact across the silk supply chain.

Resource Constraints and Efficiency

Efficient resource management, including water use, energy consumption, and waste reduction, is critical to enhancing sustainability and resilience in silk farming.

Market Dynamics and Consumer Demand

Growing consumer awareness and demand for sustainable textiles drive market opportunities for eco-friendly silk products. Brands and manufacturers that prioritize sustainability can gain a competitive edge and meet evolving consumer preferences.

Socio-economic Impact

Sustainable silk farming contributes to rural development, income generation, and livelihood improvement for silk farmers and communities. Investments in training, technology transfer, and market access empower stakeholders along the silk supply chain.

8. Case Studies and Success Stories

Case studies highlight successful initiatives and collaborations advancing sustainable practices in silk farming. These examples demonstrate the transformative impact of innovation, investment, and collective action in driving positive change within the industry.

Collaborative Partnerships

Public-private partnerships, research collaborations, and multi-stakeholder initiatives foster knowledge sharing, technology transfer, and capacity building in sustainable silk farming.

Community Engagement

Engaging with local communities, indigenous knowledge holders, and silk farming cooperatives promotes inclusive growth, cultural preservation, and social empowerment in silk-producing regions.

In conclusion, sustainable practices in silk farming are essential to mitigate environmental impact, promote animal welfare, and meet consumer demand for ethical textiles. By embracing organic cultivation methods, humane treatment of silkworms, and innovative technologies, the silk industry can achieve greater sustainability while preserving its cultural heritage and economic significance.

As the global textile industry evolves, sustainable silk farming offers a pathway to resilience, innovation, and responsible stewardship of natural resources. By investing in sustainability, transparency, and ethical standards, stakeholders can create a more equitable and sustainable future for silk farming communities and ecosystems worldwide.

Predictions for Future Applications

The versatility of silk continues to inspire new applications in fashion, technology, and medicine. Future uses may include smart textiles embedded with sensors, biodegradable packaging materials, and advanced medical implants tailored to specific therapeutic needs.

In conclusion, silk’s enduring appeal as a luxurious and versatile fabric stems from its exceptional strength, softness, and aesthetic allure. This comprehensive overview has explored silk’s scientific properties, production process, diverse varieties, and wide-ranging applications across industries. As we look to the future, innovations in silk production and sustainable practices promise to further elevate its role in fashion, technology, and global commerce.

Final Thoughts

Silk’s scientific properties and historical legacy underscore its significance as a cultural artifact and economic commodity. By understanding the intricate balance of chemistry, biology, and craftsmanship behind silk production, we gain deeper appreciation for its timeless allure and enduring relevance in an ever-evolving world.