1. Introduction

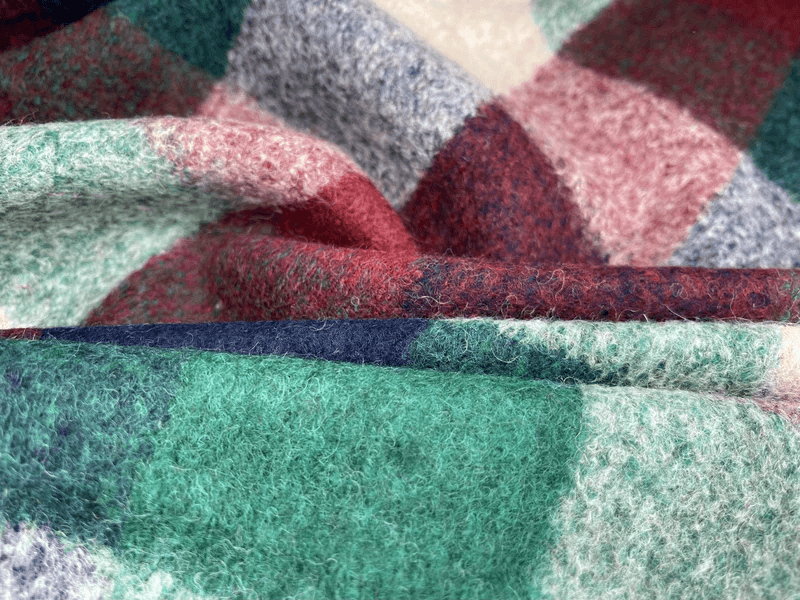

Wool, lauded for its natural, renewable and biodegradable qualities, has been a staple of the textile world for centuries. Wool harvested every year from sheep is cherished for its warmth, durability and versatility, an ecological alternative to synthetic fibers. Yet for all its innate advantages, the wool industry has enormous environmental implications as a result of climate change and demand for sustainable production.

- That Patchwork Place Wool, Needle & Thread Book

- That Patchwork Place Books Wool, Needle & Thread Book- The Go-To Guide for Wool Stitchery.

- Brimming with dozens of step-by-step photos, streamlined-stitching tricks, and professional finishing techniques, this b…

- One 16-oz bottle of Mohawk Finishing Products Liquid Wool Lube to achieve optimal results in your woodworking projects

- Great for smoothing and removing packing marks and scratches from finished surfaces

- Great for adding to your home tool kit for home improvement, restoration and renovation projects

- Simple Natural Products – Dryer balls were designed to be a natural alternative to fabric softener balls, wrinkle and st…

- Fragrance Free – Unscented laundry dryer balls can be helpful for adults and babies with sensitive skin. They are most e…

- Pack of Six – A six pack of extra-large laundry balls for dryer are provided in a canvas bag for laundry room organizati…

Although wool is renewable, its production still generates significant carbon emissions, land use and water use. With consumers increasingly demanding more sustainable products, the wool industry will have to adapt to keep up and cater to an environmentally sensitive consumer market. The technology is the engine that propels this change, delivering novel products that mitigate the ecological footprint of wool production, processing and marketing. This blog looks at the technological shifts in wool production, ranging from farm innovations to advanced processing technologies that enable an environmentally friendly and cost-effective industry.

2. Technological Innovations in Wool Farming

The wool industry is like any other system of agriculture, which presents a wide range of environmental and logistical problems. But with the rise of precision farming and genetic science, wool growers are increasingly using technology to maximise yields, improve animal welfare and cut environmental footprints. The technology listed below is transforming wool production to become sustainable and productive.

Precision Livestock Farming (PLF)

PLF or precision livestock farming is the application of cutting-edge technologies like sensors, data analytics and IoT to continuously assess and control the health and productivity of livestock. This method allows farmers to make better choices about what to feed, when to breed, and the general welfare of the herd. PLF, when applied to wool, has multiple advantages that can substantially improve animal welfare and environmental sustainability.

Sheep Sensors and IoT Devices for Monitoring Sheep

One of the main pillars of PLF is the installation of sensors and IoT devices to collect information about the health, grazing behaviour and productivity of sheep. These instruments can be used to monitor body temperatures and heartrates, which can allow farmers to spot diseases in advance or alert distressed animals. Smart-garments can also track how much each sheep is grazing, allowing pasture resources to be more effectively managed. Such data collection can minimize overgrazing and maintain the health of pasturelands by determining when livestock should be moved to alternative grazing locations.

For example, sensors that monitor the animal’s movement can allow farmers to fine-tune grazing to prevent soil erosion or excessive methane production. This also results in greater grazing productivity, better utilization of feed, and increased wool yield efficiency.

Also Read : Common Misconceptions About Wool and Sustainability

Optimized Feed Use

Another major advantage of PLF is feed optimization. Farmers could reduce waste and methane emissions by using technology to keep track of individual animals’ needs. Precision feeding systems enable farmers to provide the proper nutrients according to the age, weight and productivity of each sheep, which optimizes feed conversion. This is crucial because feed production can be very resource intensive and require land, water and energy.

Farmers could harvest more wool with these technologies without putting an unnecessarily heavy burden on the environment. This is essential for reducing the wool industry’s carbon footprint because less feed waste means less emissions and less use of resources.

Reducing Methane Emissions

Sheep methane is one of the biggest environmental problems facing wool production. Sheep are ruminants that make methane during digestion by a process known as enteric fermentation. Through PLF, farmers can reduce methane emissions by assessing the health and feeding habits of the sheep and adjusting their feed accordingly. PLF systems can also be combined with methane-reducing feed additives, including seaweed supplementation, which reduces enteric fermentation, and can reduce methane emissions by as much as 80% in some instances.

Genetic Advancements

Genetic innovation is advancing the sustainability of wool production. With the help of contemporary genetic tools, farmers can raise sheep that produce more wool, use less feed, and emit less methane.

Breeding for Less Methane Emissions through Selection.

Wool-farming breed decisions have long centred on wool quality, yield and animal durability. Yet as demand for sustainability grows, breeding programmes that target reduced methane emissions have been developed.

Selected breeding enables the determination of genetic characteristics that are associated with reduced methane generation. Farmers can genetically test and breed sheep that naturally produce less methane. This technology can dramatically minimise the ecological footprint of wool farming, thereby preserving wool production and quality. For instance, research has revealed that some breeds of sheep, including those that consume less feed and digest food more efficiently, release less methane per ounce of wool.

Incorporating methane-lowering genetics in the breeding programme allows the wool sector to actively reduce its carbon output, providing a green alternative to conventional farming systems, which depend heavily on emissions-intensive techniques.

Enhancing Wool Quality and Yield

Genetic changes also enable higher wool quality and higher fleece output per animal. By breeding sheep to develop thicker fleeces, farmers save space, feed and carbon by using fewer sheep. Moreover, increasing wool quality – resulting in thinner, denser fibres – could increase the market value of wool, and therefore reduce costs to farmers.

Sometimes, genetic studies are aimed at achieving the best quality wool at the lowest possible environmental cost, for example, by breeding sheep that require less care or are more disease-resistant, so that no antibiotics or other chemicals are needed. These genetic advancements are particularly welcome because they increase industry efficiency as well as tackling sustainability issues.

Grazing Management Technologies

Grazing management is one of the most important aspects of wool production because it directly affects soil quality, feed efficiency and farm sustainability. Overgrazing also reduces soil fertility, carbon storage, and can also increase animal methane emissions. Fortunately, many new technologies enable farmers to better control grazing to improve both ecological and economic wellbeing.

GPS Tracking and Drones for Grazing Management

Farmers use GPS and drones increasingly to track the movement of sheep and control grazing. GPS-enabled collars allow sheep to be tracked wherever they go, giving farmers insight into how many hectares of grass they are grazing, and whether some of that is being overgrazed. This enables the rotation of grazing land on a regular basis, thus reducing the loss of pastureland and maintaining the soil’s capacity to store carbon.

Drones are also an increasingly useful way to keep an eye on grazing fields. They can obtain aerial photos that help producers check the state of the pasture, spot sleepless spots, and devise optimal grazing rotations. Moreover, drones could be utilized to detect any health issues or find sheep in remote areas, thereby increasing efficiency and animal welfare.

Software Tools for Rotational Grazing

The best way to improve soil health and sequester carbon is rotational grazing, whereby livestock moves from one pasture to another so that the grass grows. Software packages that support rotational grazing management can calculate the optimal grazing time per area based on grass growth, soils, and weather, to maximise pasture use.

By lowering the risk of overgrazing and improving soil health, rotational grazing can improve the farm’s capacity to hold carbon in the soil, helping to combat climate change. Additionally, it keeps soil from erosion, retains water and improves biodiversity, making the system healthier and more sustainable.

3. Innovations in Wool Processing

Since sustainability is becoming a key priority for consumers and manufacturers alike, the wool industry is doing everything it can to minimize its impact on the environment. Wool processing, after sheep have shorn their wool, traditionally involves considerable investment in water, energy and chemicals. Yet, advances in processing methods have also provided opportunities for sustainability, both in terms of water consumption, energy consumption and dyeing. These technologies are not only reducing the ecological impact, but also boosting the efficiency and transparency of wool production.

Water-Saving Scouring Techniques

Scouring is a fundamental step in the manufacture of wool, when raw wool is cleaned from grease, dirt and vegetable matter. This step is typically water-heavy and requires large amounts of water to rinse the wool. With scouring wool getting more and more water intensive as the world grapples with the water crisis, wool producers are seeking to minimise the use of water for wool-scouring. A number of changes have been made to make this process more environmentally sustainable.

Advanced Filtration and Recycling Systems

The most significant advancement in wool production has been the creation of water-recycling systems. Traditional scouring stations pour unused water, typically polluted with grease, detergents and debris, into waterways that flow nearby. This not only consumes water but also pollutes the environment. These advanced filtration techniques use the recycled and reused water used in scouring, thus saving considerable amounts of water.

For example, some wool factories are implementing closed-loop filtration. These processes scrub wastewater, filter it for reuse during future scouring operations and remove grease and dirt. The procedure not only saves fresh water, but also reduces the environmental effects of wastewater treatment. In some cases, the water is well-treated and can be recirculated multiple times before it needs to be disposed or treated further.

Some wool mills, too, use microfiltration and ultrafiltration membranes to remove microscopic dust, and then use the water to filter that out and recycle it. These systems are now efficient and therefore viable for use in wool mills, thereby reducing the industry’s overall water usage.

Examples of Industries Using Water-Efficient Technologies

For instance, the Australian Wool Innovation (AWI)-funded wool scouring plant in Victoria is a good example of a wool production site that has incorporated water-saving practices. The plant has installed a water filtration system, which reuses up to 70% of the water that was used for the scouring, meaning that freshwater consumption is substantially decreased. Thanks to this filtration system, the plant has become one of the nation’s water-efficient wool processing plants.

Other examples include the UK textile manufacturer The Wool Marketing Board, which has teamed up with technology vendors to create water-saving scouring systems. The result of this collaboration has been the adoption of high-efficiency filtration and water treatment systems, which have significantly reduced the environmental footprint and operating costs of the wool processing facilities.

Such demonstrations show that, although the upfront cost of such technologies can be significant, the environmental and economic returns in the long term outweigh the upfront cost, and water-saving practices are a crucial part of sustainable wool production going forward.

Energy-Efficient Processing

The cost of energy, for example, is another key issue in wool processing, especially scouring, drying and spinning. Traditional wool processing consumes huge amounts of energy, many from fossil fuels. With the emphasis on sustainability, the wool industry has looked for ways to conserve energy and use more renewable energy.

Integration of Renewable Energy Sources

The most promising advancement in wool processing involves integrating renewable energy sources, including solar, wind and biomass. Renewable energy doesn’t just offset the carbon emissions from wool manufacture, but it also enables firms to meet an increasing need for sustainable manufacturing.

Some wool mills, for instance, use rooftop solar panels to run their machines. In places where wind is strong, wind turbines can also be deployed to add power. Powered by renewable energy, such plants can greatly reduce their dependency on grid power, which is usually generated from fossil fuels such as coal and natural gas.

The most impressive example of a renewable energy-driven wool processing plant is New Zealand-based wool scouring company Clean Green Wool. The group has deployed a mix of solar panels, wind turbines and a geothermal heating system to supply all the energy needed to operate its wool-processing facility. In addition to using renewable materials, Clean Green Wool has reduced its carbon footprint and energy consumption, giving consumers a product that’s both sustainable and efficient.

Low-Temperature Enzymatic Treatments

A primary place where energy is being saved is in the creation of low-temperature enzymatic reactions to counteract energy-intensive processes. Wool scouring is the ancient process of washing wool at high temperatures with strong chemicals. Such treatments burn a lot of energy to heat the water to the desired temperature, adding to the carbon footprint of wool production.

For its part, researchers and textile suppliers have been developing enzyme-based ways of cleaning wool at much lower temperatures. These methods use natural enzymes that dissolve grease, dirt and other impurities from wool fibres without heating. Thus, they consume much less energy — making them both more sustainable and affordable.

For instance, an Italian wool mill now uses enzymatic treatments to melt wool at temperatures 30-40°C lower than conventional processes. This has cut the plant’s energy use by more than 20% and illustrates how technology can help wool manufacturers conserve fossil fuels and mitigate their impact on the environment.

Sustainable Dyeing Methods

Another process in wool manufacturing where sustainable development depends on innovation is the dyeing process. The traditional dyeing of wool involves massive wastes of water, chemicals and energy that may have negative effects on the environment. But thanks to advances in dyeing technology, the ecological footprint of this process at the heart of wool production is gradually diminishing.

Natural and Plant-Based Dye Innovations

Increasingly, wool producers are using natural and plant-based dyes as an eco-friendly alternative to chemicals. Plant-based dyes, made from plants, fruits and vegetables, are biodegradable and not contaminated by the harmful chemicals that conventional dyeing requires. These organic dyes are not only greener, they provide distinctive and full color options that satisfy eco-conscious consumers.

One Indian wool manufacturer, for instance, has started experimenting with plant dyes derived from organic sources of indigo, turmeric and pomegranate skins to produce a number of different colours. With these environmentally friendly dyeing techniques, the company saved water and eliminated noxious chemical runoff, an environmental problem with old-fashioned dyeing.

Meanwhile, a number of firms are playing around with the idea of using waste, including food waste or farm products, to make dyes. This approach both minimizes waste and synthetic dyeing chemicals, offering a circular solution to the ecological dilemma of wool dyeing.

Digital Dyeing Technology

A second revolutionary way of reducing the environmental footprint of wool dyeing is digital dyeing. It employs computer-operated machinery to spray the dyes more efficiently and accurately, without using massive amounts of water and chemicals. Older methods of dyeing often require multiple rinses, which use up a huge amount of water. With digital dyeing, however, the dye is transferred into the wool at a controlled rate, saving a lot of water.

One of the most famous instances of digital dyeing was an arrangement between the textiles company Kornit Digital and a leading European wool brand. Kornit’s digital dyeing machines inject pigments directly into wool fibres, eliminating the need for water and chemicals. Moreover, digital dyeing machines offer increased accuracy since the dye is applied less to each garment and the colors are accurately matched.

This technology likewise makes dye lots smaller, which allows woollen producers to maintain stock and minimize waste. As the market for on-demand production continues to expand, digital dyeing might play an increasingly important role in the environmentally friendly production of wool and fulfil the ever-expanding market for sustainable and customisable wool products.

4. Enhancing Traceability and Transparency

Traceability is a central concept in the wool industry, especially at a time when consumers care about sustainability and fair supply. Technology facilitates greater transparency so that customers can purchase wool that resonates with their beliefs. By integrating technologies such as blockchain and smart tags, wool is taking the first steps to making it easier for people to trust that sustainability claims are true and products are responsibly sourced.

Blockchain Technology

Blockchain is a distributed digital ledger system that stores transactions transparently and securely. With regards to the wool sector, the blockchain is being utilized to record the entire wool supply chain from the farm to the consumer. The technology guarantees that wool products can be tracked and sustainability claims can be verified.

By following wool through every step of the supply chain, blockchain makes sure that wool was responsibly obtained, ethically processed, and environmentally sustainable. It not only gives consumers visibility, but also fights greenwashing, where companies falsely assert their sustainability.

Australian woollen manufacturers, for instance, have started using blockchain systems to map wool from sheep to fibre. These enable customers to scan a QR code on an item and see its entire production process, verifying the wool’s provenance and sustainability. Such systems are empowering consumers to make informed decisions and hold businesses accountable for their ecological and moral statements.

Smart Tags and QR Codes

Another method of bringing more traceability and transparency to wool products are smart tags and QR codes. Once product data is embedded into these tags, consumers can quickly learn where the wool comes from, how it’s processed, and whether it has sustainability labels.

Brands such as Patagonia and Icebreaker have already begun printing QR codes on their wool products, enabling consumers to scan the code and find out all about the wool’s production history, where it came from, how it was processed, and whether it meets certain sustainability standards. This technology establishes consumer confidence by giving transparent, easy-to-read data about the ecological impact of what consumers are buying.

5. Supporting Carbon Reduction through Technology

Wool stands at a critical moment in the way it addresses its own carbon footprint. Wool is a natural, renewable material, but the carbon impact of its production – particularly sheep-emitted methane – can be enormous. But technology is opening up new opportunities to offset these emissions and encourage carbon savings. From satellite imagery to methane-reduction feed additives, tools are now available to farmers to measure and mitigate their carbon emissions, thereby ensuring a more sustainable and environmentally responsible wool sector.

Carbon Sequestration Tools

Perhaps the best technology for mitigating the wool industry’s carbon emissions is the potential to store carbon in the soil through regenerative agriculture. Regenerative agriculture addresses soil health, biodiversity and captures carbon through organic matter. Wool farms, by adding nutrients to soils and improving their structure, can capture and store carbon dioxide to offset the greenhouse gas emissions that come from animal agriculture. But measuring and testing carbon sequestration on wool farms was always difficult given the scale of agricultural operations.

Carbon Capture from Satellite Images and Artificial Intelligence?

Recent advances in satellite imaging and artificial intelligence (AI) are breaking down these barriers by empowering farmers to track and quantify carbon sequestration on their land. Satellite-based technologies could measure the carbon concentration in soils and detect changes over time, so farmers could observe the impact of their regenerative practices on carbon capture. These technologies employ spectral imaging to measure fluctuations in vegetation cover, soil organic matter and plant wellbeing, all key indicators of carbon storage.

Artificial intelligence is assisting us as well in examining this data. With machine learning algorithms, AI can analyze thousands of satellite photos to detect carbon sinking in landscapes. In blending satellite data with other data, including soils and farm management systems, AI can give farmers a real-time understanding of the way their land stores carbon and where to invest.

For example, the precision farming firm Regrow leverages satellite and AI data to provide farmers with information on the health of soils, the potential for carbon sequestration and whether regenerative techniques such as rotational grazing are effective. This enables farmers to use data to make informed decisions about how best to manage their farm practices in order to capture more carbon while maintaining or increasing wool yields.

Farmers’ Tools for Estimating and Counterbalancing Their Carbon Footprint.

Beyond measuring carbon sequestration, farmers now have access to tools to determine and offset their carbon footprint. Websites such as Carbon Footprint Ltd. and Cool Farm Alliance offer calculators that allow farmers to estimate the amounts of carbon released from their activities, including animal-derived methane and fertiliser-derived emissions. Knowing their carbon footprint helps farmers understand where emissions can be reduced, whether by moving to more efficient agriculture or to renewable energy.

These platforms also provide tools for farmers to offset emissions by buying carbon credits or partnering with schemes to restore forests and other carbon-bearing habitats. Wool farms have already started using carbon offset schemes to compensate for their emissions and ensure that their wool isn’t contributing to global warming.

Lastly, carbon sequestration and emissions calculators provide wool producers with the ability to offset their carbon emissions and take climate action. These technologies enable more precise measurements of carbon capture, facilitating sustainability among farmers and the ability to access carbon offsets.

Methane-Reducing Feed Additives

Methane is one of the world’s most powerful greenhouse gases, warming the planet hundreds of times faster than carbon dioxide. Sheep, like all ruminants, generate methane as part of the digestion process through enteric fermentation in the rumen. It is belched into the atmosphere, adding to the wool industry’s carbon footprint. But new research into methane-reducing feed additives offered an exciting way to cut these emissions without harming sheep health or wool quality.

Use of Seaweed-Based Supplements

Seaweed is perhaps the most promising feed additive for sheep to help eliminate methane emissions. The studies have indicated that some seaweeds, particularly Asparagopsis, could greatly decrease the emission of methane during digestion. Research has shown that introducing a small dose of Asparagopsis to sheep can also reduce methane emissions by as much as 80 per cent. This discovery is groundbreaking because it offers a simple, organic and affordable alternative to one of the largest contributors to greenhouse gas emissions from wool production.

The seaweed acts by repressing a certain enzyme in the sheep’s digestive tract that produces methane. Adding this seaweed to the grain can enable farmers to reduce methane emissions while still offering a quality food source for their livestock. Seaweed supplements for feed are already being tested in several countries, including Australia and New Zealand, where sheep farmers have observed a drop in their flocks’ methane emissions.

Case Studies and Studies – Proving Effectiveness and Scalability.

Seaweed-based methane-reducing feed supplements remain in their infancy, with several trials underway across multiple regions and climates. But the outcome has been good, and the scale of this technology is one reason why it might take off. In Australia, tests by the Commonwealth Scientific and Industrial Research Organisation (CSIRO) have shown that seaweed-based additives can lower methane levels in cattle and sheep.

Aside from seaweed, other feed additives – including tannins from some plants – have also proved effective at reducing methane. Tannins act by modifying the microbial community in the rumen, reducing methane production. Such additives are being studied and refined to make them effective and safe for sheep, and economically feasible for farmers to use.

Feed additives might be a straightforward and cost-effective remedy, but they are difficult to scale up to what is needed for the wool industry as a whole. Good quality seaweed, for instance, can prove a challenge in some parts of the world. Yet, as research advances and production techniques advance, these options might soon be universal, allowing the wool industry to dramatically reduce its methane emissions and carbon footprint.

6. Consumer-Focused Innovations

Agri-technical advances are helping to improve the sustainability of the wool industry, but consumer technologies are equally important. As awareness of the environmental problem increases, consumers increasingly want to adopt environmentally conscious decisions. Digital marketplaces, upcycle technologies and recycling are allowing consumers to access sustainable wool products and become a part of the circular economy.

Online Marketplaces for Ecological Wool Products.

During the past few years, online communities have been a very useful vehicle for selling ethical wool. Online marketplaces, apps and websites are now providing consumers with easy access to certified sustainable wool products to help them make good buying choices. These marketplaces display brands with a focus on responsible production, carbon minimization and sustainable materials, which allows shoppers to easily purchase brands that match their values.

Marketplaces For CSC Accredited Wool Brands Online

Such a platform is The Good Trade, a website that promotes ethical and sustainable clothing brands, including those that use certified sustainable wool. Brands on the platform are screened to ensure sustainability standards such as responsible sourcing, low-carbon production and supply chain transparency.

Likewise, sites such as Woolmark have established digital tools for consumers to discover wool products that conform to specific sustainability standards. These platforms are not only an advertisement for ethical wool brands, but also a place to learn more about the environment-related factors behind wool products, and make informed purchasing decisions.

Apps Bringing Wool Products to Consumers’ Awareness of their Impact on the Environment.

Some apps are also launching to give consumers an idea of what’s being produced from wool. Such apps give you an idea of how wool has been made, how much it’s using up water and where it came from so that you can buy more sustainably. For example, the “Buycott” app enables consumers to scan product barcodes and read about the environmental and social effects of various products, such as woollen clothing. This sort of app empowers consumers to choose brands that are committed to sustainability and steer clear of brands that are less transparent.

Making sustainable wool products available, and informing consumers on their ecological impact, these online outlets are turning the tide to the green side. They also demand that firms become more sustainable in order to respond to increasing demand for eco-friendly products.

Upcycling and Recycling Technologies

An additional emerging consumer innovation is the upcycling and recycling of wool products. As the wool supply chain transitions to a circular economy, these technologies are extending the life of wool fabrics, eliminating waste and minimising the need for new raw materials.

New Machines and Methods for Turning Discarded Wool Into Superior Recycled Goods.

Recycling wool is an efficient and sustainable practice to extend the lifespan of wool garments while minimising their carbon emissions. Recycling technologies have made it much easier to convert discarded wool fibres into new recycled wool fibers. Mechanical recycling, for instance, combines worn wool garments into fibres, which can be spun into new yarn for clothing, textiles and other products.

- TOP QUALITY, HEAVY DUTY SOFTNESS – strong, water resistant, new black 600D polyester material is by far superior in qual…

- GENEROUS SIZE – our full length 60 inch + 5 inch gusset storage garment bag is designed to fit even the longest (54-59”)…

- 100% BREATHABLE – when it comes to storing these seasonal clothes, robes, formal and evening ware, air circulation withi…

- NATURAL BOAR BRISTLE CLOTHES BRUSHES ARE THE BEST YOU COULD BUY. A cheaper lint brush for clothing will be made from syn…

- PERFECT CLOTHES BRUSH FOR MEN AND THEIR BLACK WOOL SUITS. Very versatile used as a lint brush for furniture. Excellent a…

- ERGONOMIC DESIGN: Designed for comfortable grip and effortless use, ensuring a smooth and efficient brushing experience …

- KEEP YOUR FAVORITE CLOTHES FRESH & PROTECTED: Whether it’s your cherished evening gown or that special winter coat, our …

- EASY ACCESS, LESS STRESS: No more digging through your closet! The smooth, durable side zipper allows you to easily sele…

- CEDAR BLOCKS FOR A FRESH SCENT: Each garment bag comes with 4 aromatic cedar blocks, which naturally leave your clothes …

Other than mechanical recycling, chemical recycling systems are being created to recover wool fibres from garments that are too old or damaged for re-use. These involve pulverising the wool into its chemical components and spinning it back into new fibres. Chemical recycling, while still experimental, promises to cut down on waste and provide a closed-loop system for wool production.

Projects Facilitating Access to Wool Recycling for Consumers and Businesses

Some programs are making wool recycling more accessible to consumers and businesses. The “Woolcycle” program in Australia, for instance, takes old wool garments to be recycled and reprocessed. This initiative reduces the environmental footprint of wool clothes that would otherwise be thrown in landfill. Participants enable consumers to drop off their unwanted wool items in the participating outlets, which are then recycled.

Likewise, brands such as Patagonia and The North Face are running take-back schemes where customers can send their old woollen clothing back to be recycled or upcycled. These brands are not only opening up a market for recycled wool, they’re making it easier for consumers to reduce their environmental footprint by lengthening the shelf life of their wool products.

7. Wool Production: Technical Problems and the New Promise?

However, despite promising innovations and technological advancements in wool production, there are many obstacles that stand in the way of implementing these technologies across the industry. These issues include high costs, technical limitations and broad industry collaboration.

Barriers to Adoption

High Costs for Small-Scale Farmers

A key impediment to the deployment of new technologies in wool processing is the expense of such technologies. Even for small farmers, it’s hard to justify the upfront costs of satellite imaging, artificial intelligence, and feed additives. And the cost of keeping these technologies up-to-date and operating would be too great for some farmers to bear when they are already on razor thin margins.

Technical Restrictions in Certain Areas or Climates.

Certain technologies, like satellite images and AI, require constant internet access and high-tech devices that are not always available in the countryside or the outer reaches of the continent. This can inhibit the implementation of these technologies in some areas, particularly in the developing world where wool production plays a key economic role.

Potential Solutions

Supportive Government Assistance and Tax Breaks on Use of Green Wool Technology

By providing subsidies, grants and incentives, governments and international agencies can provide key support for the implementation of sustainable technologies in wool production. These payments can mitigate the initial cost of introducing new technologies and make them more accessible to smallholder farmers. Additionally, governments can support technical assistance and training to educate farmers on how to use new technologies.

Innovative Collaborations — Between Farmers, Scientists, and Technology Agencies.

Farmers, scientists and tech startups can collaborate to help speed up the adoption of sustainable technologies. Through partnership, these parties can achieve sustainable solutions that are tailored to wool processors’ unique needs. Collectively tackling technology access and technical assistance can ensure that all farmers, large and small, can reap the benefits of sustainable practices and innovations.

Dhanya Nair is a fabric Lover and a mom. She offers a unique perspective on the intricacies and history of fabric and specializes in bringing the unique narratives of textiles to life.